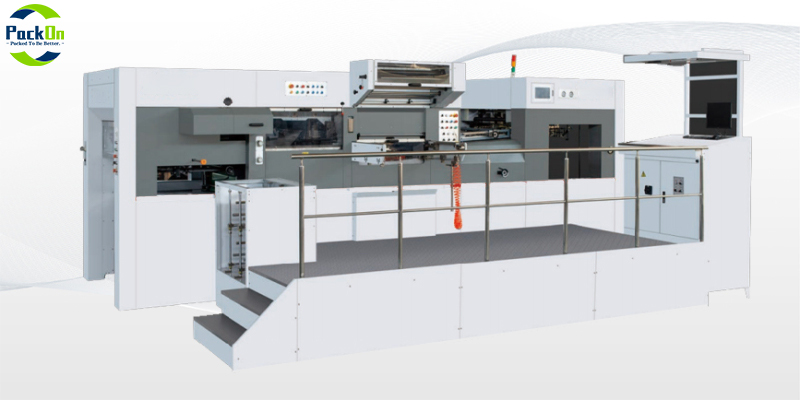

HF-1060/1300/1450MTE/STE/MT

Detail Information

Product Description

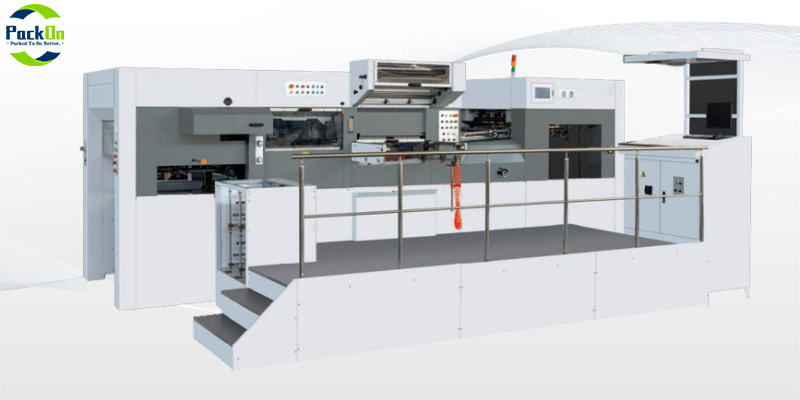

The fully automatic flat-bed hot stamping die-cutting machine is a new generation of fully automatic flat-bed hot stamping machine HF-1060MTE with both longitudinal and transverse hot stamping functions developed by our company after many years of design of automatic flat-bed hot stamping machine. It is mainly used for die-cutting, hot stamping, creasing and cold pressing of cartons, cartons and trademarks in the packaging and decoration industry. In particular, various high-end and fine printed products, such as cigarette boxes, wine boxes, gift boxes, small appliance boxes, cosmetic boxes, etc., can be subjected to ordinary hot stamping and cold pressing on this machine to obtain three-dimensional and beautiful printed products. The machine is automated from paper feeding, die-cutting, hot stamping to paper collection. It can realize functions such as automatic detection, display of faults, and non-stop sampling. It also has the advantages of high die-cutting pressure and high registration accuracy. The main transmission system of the machine is equipped with a pneumatic clutch and a braking device; the main sprocket shaft is equipped with a torque limiter (safety clutch); and multiple safety detection electric eyes and safety devices, etc.; these can avoid injuries to operators and damage to equipment caused by emergencies, and fully ensure the safety of people and equipment.

The four-suction, five-feed high-precision paper feeding feeder head can meet the needs of thin paper and various types of cardboard and corrugated paper, and realize smooth paper feeding under high-speed conditions; it is equipped with a gantry-type pre-stacking paper mechanism, and the main and auxiliary paper feeding tables are alternated to achieve non-stop production.

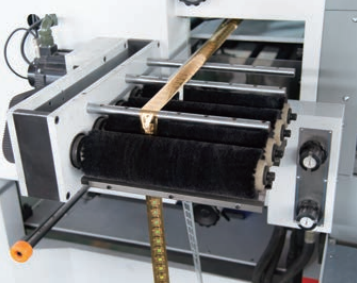

The vacuum paper feeding system realizes stable feeding of thin paper; the push-pull dual-purpose pull gauge can be used for stable positioning of paper at high speed; the paper feeding wheel quick adjustment mechanism improves work efficiency.

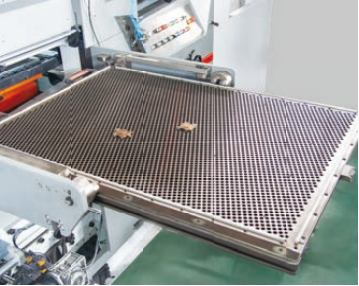

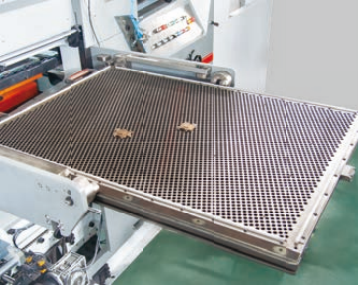

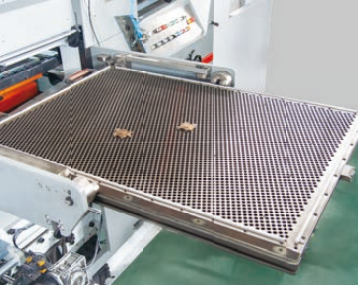

Anti-deformation heat-resistant cast iron honeycomb panel; pressure regulating device, using gapless ball screw pressure regulation is accurate and reliable. 20 heating temperature zones, independent temperature control, precise control of heating system, effective control of the temperature stability of the hot stamping plate, ensuring more balanced temperature control of the entire heating system and quick response.

The steel plate fine-tuning mechanism facilitates quick correction of the bottom mold and improves work efficiency.

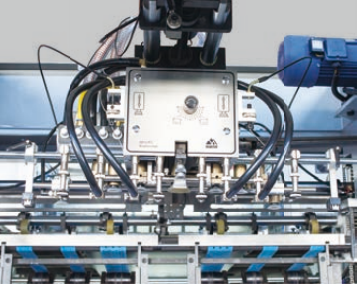

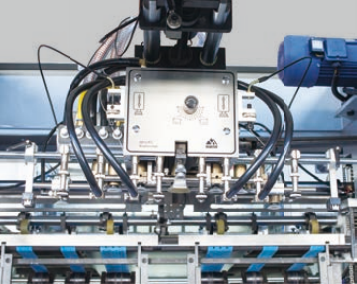

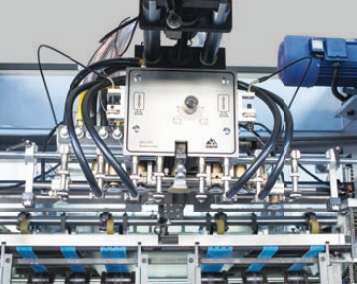

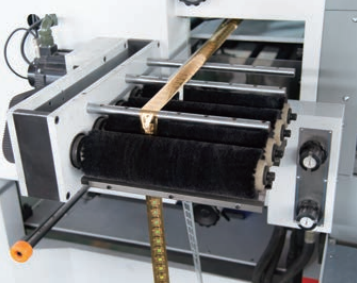

Longitudinal three-axis high-point foil feeding system, retractable foil rack for quick and convenient foil replacement, horizontal two-axis servo foil feeding system and broken foil detection system.

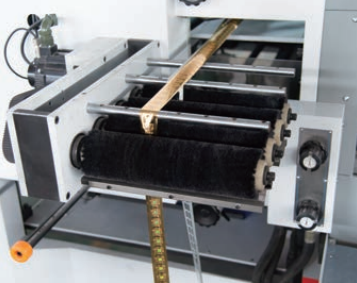

External longitudinal fleece roller foil collection system facilitates waste recycling and reuse.

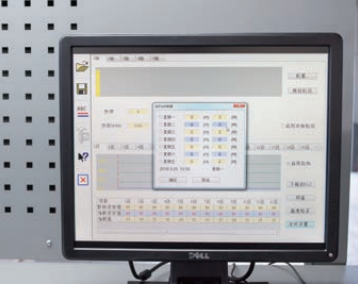

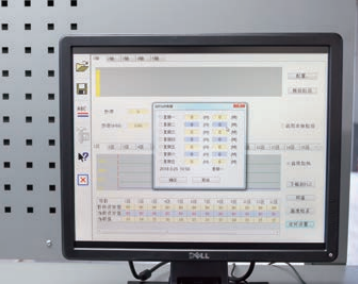

The intelligent operation system automatically calculates and skips different product steps to save aluminum foil to the greatest extent.